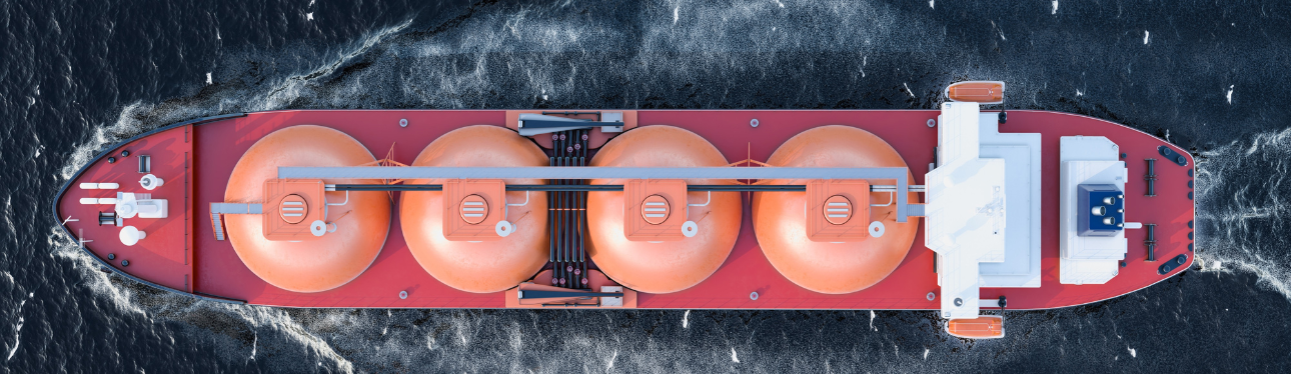

LNG & Maritime Safety & Security

The safe and secure operation of LNG facilities and maritime operations is essential to maintaining public trust and protecting communities, the environment, and critical infrastructure. As global demand for LNG and maritime services continues to grow, operators face increasingly complex challenges in safety, security, and regulatory compliance. Navigating these challenges requires a deep understanding of U.S. and international regulations, robust risk management practices, and experience in both onshore and offshore operations.

End-to-End LNG and Maritime Risk Management Solutions

AcuTech has spent over three decades helping clients manage the risks associated with LNG and maritime operations. Our consultants bring a unique blend of operational, regulatory, and process safety expertise—ranging from U.S. Coast Guard compliance and FERC approvals to Waterway Suitability Assessments, hazard analyses, and quantitative risk assessments. We have guided projects through the full spectrum of LNG operations, including storage, transfer, and bunkering, while ensuring alignment with international standards such as NFPA 59A, IMO’s IGF Code, and SGMF guidelines.

Whether assessing hazard scenarios, designing emergency response plans, or navigating regulatory approvals, AcuTech integrates proven risk management methodologies with practical, real-world insights. By combining decades of experience, regulatory relationships, and technical expertise, we help clients operate safely and efficiently, delivering peace of mind across every stage of LNG and maritime projects.

Explore how Process Hazard Analyses (PHAs), Quantitative Risk Assessments (QRAs), and other critical studies work together to identify and mitigate LNG risks.

Read the full blog series to learn best practices, risk management strategies, and lessons from industry experts.

Specialized LNG & Maritime Expertise

- LNG export/import terminal safety & security support

- LNG bunkering (facility, ship-to-ship, and truck-to-ship) regulatory strategy

- Navigation safety, pilotage, and tug service assessments

- Hazard analysis, risk mitigation, and operational compliance support across LNG and maritime projects

Regulatory Support & Compliance

- U.S. Coast Guard (USCG) Compliance (33 CFR Parts 105, 126, 127, 154)

- Federal Energy Regulatory Commission (FERC) LNG Project Support (LOI, WSA, LOR, terminal siting, Environmental Impact Statement)

- Maritime Transportation Security Act (MTSA) Facility Security Plan (FSP) & Vessel Security Plan (VSP) development

- Cybersecurity compliance integration into FSA/FSP

- International port security and emergency management consulting

Risk Assessment & Analysis

- Independent Risk Assessments (IRA) for LNG Deepwater Ports (DWP)

- Waterway Suitability Assessments (WSA)

- Operational Risk Assessments (ORA) for LNG bunkering and waterfront facilities

- Security Risk Assessments (ANSI/API 780 methodology)

- Quantitative Risk Analysis (QRA)

- Process HAZOP and SIL Determinations

- Facility Siting Studies

- LNG Carrier Transit Logistics Studies & Simulation

- Transportation Safety & Route Risk Analysis (ArcGIS, consequence modeling)

Emergency & Security Planning

- Emergency Response Plan (ERP) development and updates

- All-hazards emergency planning (ICS/NIMS aligned)

- LNG and petrochemical hazard analysis (Sandia studies, NFPA 59A)

- Security Planning & Vulnerability Assessments

- Stakeholder engagement, tabletop exercises, and navigation simulations

Supply Chain & Business Continuity

- Sanctions compliance and ghost fleet risk advisory

- Supply chain due diligence aligned with ISO and AEO/CTPAT programs

- Global business continuity planning for fixed facilities & marine operation

AcuTech’s consultants are well versed in codes and standards developed by industry bodies and will refer to these as well as each client’s local jurisdiction codes and standards. A sampling of the relevant codes and standards can be found below.

- NFPA 59A. The National Fire Protection Association (NFPA) Standard for the Production, Storage, and Handling of Liquefied Natural Gas (LNG) outlines requirements for LNG facility siting, design, construction, and operation to mitigate fire and explosion hazards.

- API 625. American Petroleum Institute (API) Standard 625 covers the design and construction of large, welded, low-pressure storage tanks for LNG.

- ISO 14726. This International Organization for Standardization (ISO) standard provides guidelines for the identification and marking of piping systems used in LNG installations to facilitate safe operation and maintenance.

- ASME B31.3. American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section B31.3, outlines requirements for the design, construction, inspection, and testing of process piping systems, including those used in LNG facilities.

- IGC Code. The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), developed by the International Maritime Organization (IMO), sets forth safety standards for LNG carriers and terminals.

- EN 1473. This European standard provides guidance on the design and safety of LNG installations, covering areas such as spill containment, ventilation, and emergency response planning.

- USCG Regulations. The U.S. Coast Guard (USCG) imposes regulations specific to LNG facilities operating within U.S. waters, ensuring compliance with safety, security, and environmental protection requirements.

- FERC Regulations. In the United States, the Federal Energy Regulatory Commission (FERC) oversees the siting, construction, and operation of LNG import and export terminals, imposing regulatory requirements to protect public safety and the environment.

- IMO & ISPS Code. The International Maritime Organization (IMO) and International Ship and Port Facility Security (ISPS) Code provide global security standards for vessels and port facilities, including LNG terminals.

- ANSI/API 780 & 753. Standards for security risk assessments and vulnerability analysis for facilities handling hydrocarbons, including LNG operations.

- NFPA 70 / NEC. National Electrical Code (NEC) requirements for electrical design and safety in hazardous areas typical of LNG facilities.

- NFPA 59 / Fire Protection Standards. Additional NFPA standards addressing fire protection systems, detection, and suppression in LNG storage and processing environments.

- ISO 21500 / Project Management Guidelines. International standards for project management, relevant to LNG terminal design, siting, and construction.

- ISO 31000 / Risk Management Guidelines. International standards for risk assessment, risk management processes, and decision-making for high-hazard facilities like LNG terminals.

- ICS / NIMS Standards. Incident Command System (ICS) and National Incident Management System (NIMS) guidelines for emergency response planning and coordination.

- AWWA & API Transport Standards. Standards covering LNG carrier design, navigation, and transport risk mitigation, including route analysis and tug/pilot requirements.

- ISO 45001. Occupational health and safety management standards, applicable to personnel safety in LNG and maritime operations.

AcuTech consultants have contributed to the following standards, codes and programs:

- Our consultants served as the LNG, Petroleum & Chemical Industry Sector Coordinator for the Risk Analysis & Management for Critical Asset Protection (RAMCAP Plus) project. They developed a security vulnerability assessment method for LNG facilities.

- AcuTech was instrumental in creating the American Petroleum (API) Security Risk Assessment Standard 780 which we use for LNG security assessments and waterway sustainability assessments.

This paper describes the difficulties in applying traditional QRA to intentional acts, and how security risks are being estimated by the LNG industry and other industries globally.